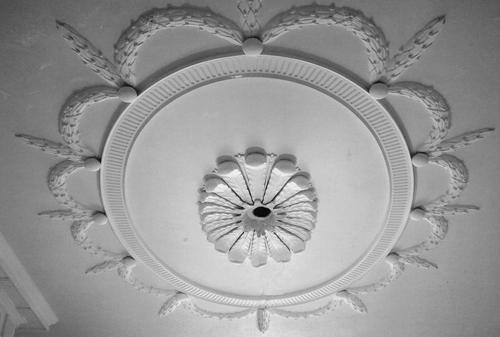

Stucco molding on the ceiling is embossed decorative ornament, room interior decoration element. It gives the interior decoration of the premises a unique and noble look.

Ceiling design

A huge selection of decorative elements makes it possible to create various original solutions. Decorative stucco molding is glued to the ceiling, for example, to make places for curtains and lighting fixtures invisible.

This method of decorating the ceiling space has been used for more than one hundred years - such decorations were once quite common in the estates and mansions of the nobility, and at the present moment such decor is mainly an element of the classical interior in large apartments and country houses.

The previously used geometric strict ornaments were replaced by floral motifs - stucco on the ceiling, the photo of which is presented in this article, provides for the creation of a sense of originality and lightness. The decor looks even more stylish if it is gilded.

When choosing elements to create your ideal interior, you need to decide on the material of its parts. For example, decorative stucco molding on the ceiling under a bulky chandelier in the form of a plaster rosette is considered a very advantageous element in the design of the space. It will emphasize the beauty of the lighting fixture itself, while hiding all traces of the installation.

It is worth noting that do-it-yourself stucco molding on the ceiling is done quite easily, which we will talk about further.

To begin with, it is worth considering that for effective work we need a set of tools and certain materials.

materials

At the moment, stucco molding can be performed using modern materials, as well as using classic materials that have been used for a long time.

Traditional stucco on the ceiling involves the use of soft stone, alabaster, and gypsum, while modern decor elements are made from the following materials:

Tools

The decoration of the ceiling with stucco molding is carried out using the following devices and tools:

- sandpaper;

- containers for mixing the solution;

- PVC molds;

- spatula, the width of which exceeds the shape parameter by five centimeters;

- special forms, which are made of steel and coated with Teflon on top.

Mounting materials

Based on the type of ceiling surface, in order to attach the necessary elements, either special glue, or liquid nails, or PVA glue (periodically and dowels) are used. Specialists prefer to use liquid nails, as they hold the stucco remarkably well, while being undemanding to the surfaces that are connected. They perfectly hold glued parts, they are used in dry rooms, as well as in places with high humidity (kitchens, bathrooms, bathrooms).

After application, the stucco molding is grasped for thirty minutes, and in a day the polymerization of adhesive solutions occurs.

Gypsum Features

From the name it is clear that gypsum stucco on the ceiling is made of gypsum, which has a huge number of advantages, for example, durability, naturalness and environmental friendliness. It is resistant to fungi, does not emit toxic substances. Among the minuses can be called only fragility and relatively heavy weight. It is chosen by grade G-7 or higher. The property of gypsum to expand after drying is convenient for the manufacture of stucco molding, since in this way small particles of material are able to penetrate into any holes, even of a complex shape of the casting.

Types of plaster moldings

In the interior, similar stucco molding can be found on the ceilings and on the walls. The range of such decor is very wide, and any of its varieties has a huge number of variations.

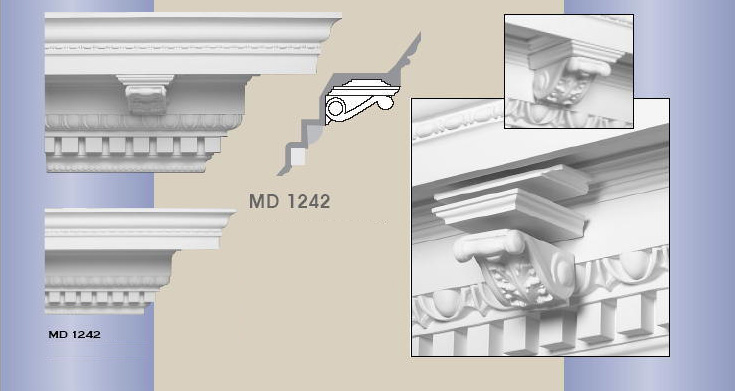

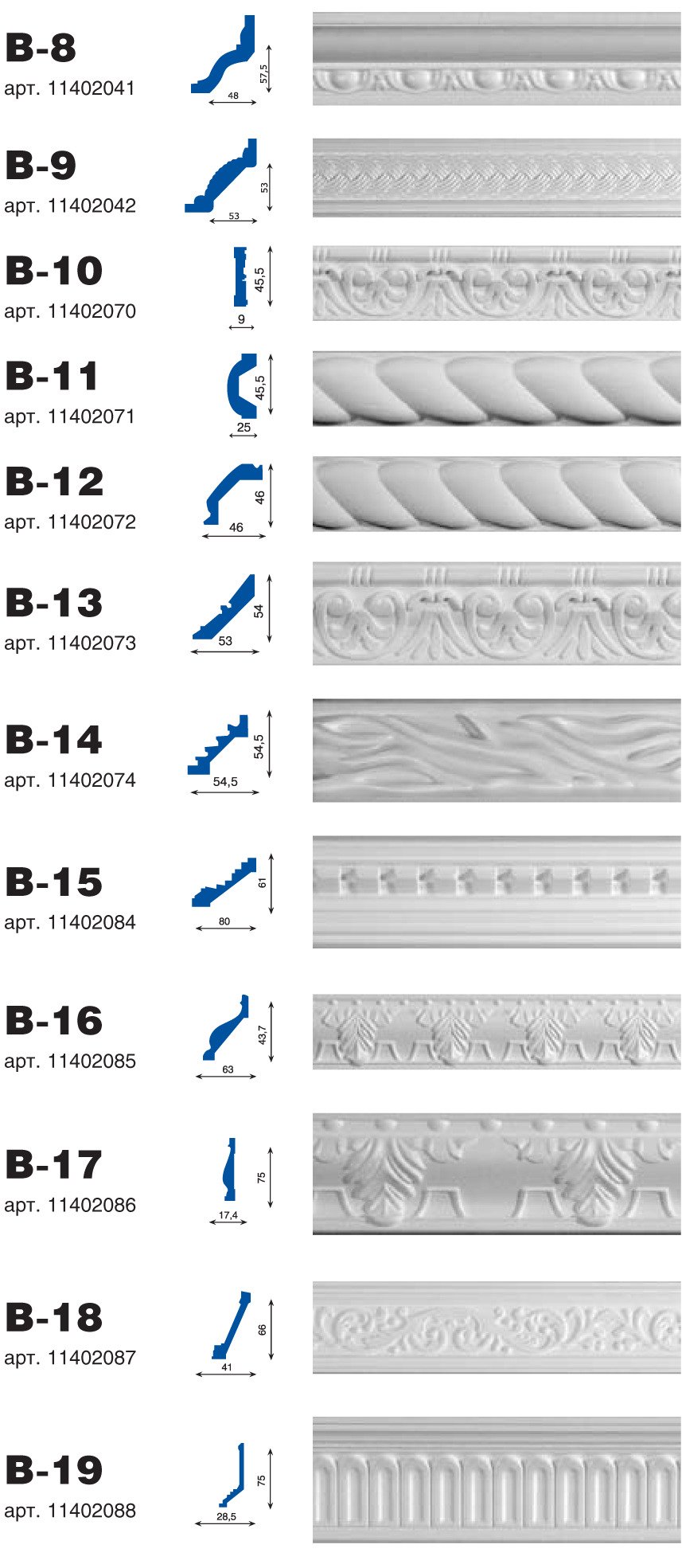

It is represented by moldings, cornices, friezes, as well as separate compositions. Cornices are used to decorate the joints between the ceiling and walls, as well as to hide the seams between these planes. They are smooth, very simple, and may contain various curls and ornaments. Of course, the more complex the composition, the more expensive the cornice.

Gypsum moldings are decorations for the upper area of the wall in the form of a figured plank. They are somewhat similar to cornices, but mainly play a decorative role, combined with original corner elements, thereby creating a unique composition. In addition, walls can be decorated with moldings (this gives them a more expressive look).

Wall friezes are decorative strips framing the wall around the perimeter. Basically, gypsum friezes are used when pasting a room with two often contrasting ones. In this case, such wallpaper is separated by a frieze, which allows you to create a unique design of the room.

For refined interiors, exclusive plaster compositions can also be created, which will be the central point of the room. Such a pleasure is not cheap, since in this case hand-made stucco molding is made to order, which means that it has no analogues.

Do-it-yourself gypsum stucco on the ceiling

Classical alabaster or gypsum stucco on the ceiling is created in the following way:

Creation of polystyrene and polyurethane moldings

Gypsum elements are the most difficult to manufacture, since polyurethane stucco on the ceiling, like foam plastic, is produced by manufacturers in finished form, and it is enough just to stick it on the surface. It is worth noting that the decoration with such materials is not inferior to the classic gypsum ceiling either in quality or visually.

Professionals recommend that all elements of the stucco creation, regardless of where it will be located (along the perimeter of the ceiling or in its center), should be kept in the room where the repair is taking place for about a day. This is necessary so that the finished products can adapt to the humidity and temperature in the room and do not change their parameters after installation.

Currently, when developing a room design, specialists often provide stucco molding on a stretch ceiling, which is installed directly under the canvas of this design. Immediately after installation of all decor elements, you can paint them.

When choosing a ready-made one, it is possible to buy special glue solutions, which are produced by manufacturers of stucco elements and their compounds. In addition, customers are offered various materials to fill the resulting gaps.

Polymer stucco elements are coated with an adhesive solution, after which they are attached to their designated place on the ceiling. Once the adhesive dries, the foam products can be finished using water-based paints.

Repair

Stucco molding on the ceiling needs periodic repairs. The gypsum ornament is updated by applying linen drying oil, whitewash or oil paint with a specially designed brush.

If the relief is smeared, while there are many layers of different paints on the elements, the surface is thoroughly cleaned, the missing parts are restored, and the structure is also strengthened. If the gypsum has become loose from time to time, then the products are replaced with new ones made from various modern materials.

Finishing in a classic style does not lose popularity over the years, and stucco on the ceiling is one of the ways to give the room austerity and at the same time sophistication. Geometric stucco patterns, tiles imitating stone or floral motifs will not only decorate the ceiling, but also allow you to visually adjust the proportions of the room, focus on the chandelier or wall decor. Our article will tell you how to choose stucco elements and fix them on the ceiling with your own hands.

Types of stucco for ceiling decoration

In modern interior decoration use three types of materials that allow you to decorate the ceiling with stucco elements:

- gypsum or alabaster;

- polyurethane;

- expanded polystyrene - fine-grained foam.

What are the advantages and disadvantages of different types of stucco, and which one is better to choose? Let's try to understand this issue.

plaster molding

Traditionally, stucco on the ceiling is made of plaster. Complex stucco elements are cast using molds and, after hardening, are attached to the surface. More simple details can be made in place using a template. This work is quite painstaking and requires high skill of finishers, and therefore it is not cheap.

Advantages of gypsum stucco:

- environmentally friendly material;

- gypsum does not burn and is completely fireproof;

- gives the ceiling a unique design;

- when using a high-quality form, it allows you to create decor with the smallest patterns;

- allows coating with paint on any basis;

- gypsum stucco can be made with your own hands, embodying original ideas.

Flaws:

- labor-intensive process of manufacturing elements;

- the decor is quite heavy and requires the use of special glue or pins;

- gypsum is gradually destroyed by changes in temperature and humidity.

If you have artistic taste, time and skills, you can make such stucco molding with your own hands. This will significantly save on paying for the work of the masters, but it will take quite a lot of time and require accuracy.

Note! Gypsum stucco may require repair or replacement of individual parts over time, so casting molds must be preserved.

Polyurethane decor

An easier and faster way to decorate the ceiling with stucco is to use ready-made polyurethane decor. In the shops of finishing materials there is a huge selection of ceiling borders and other elements for decorating the ceiling from this high-strength and lightweight material.

Advantages of polyurethane:

- light weight;

- elements are easily cut and mounted on glue;

- strength and durability;

- moisture resistance;

- environmentally friendly material without foreign smell;

- polyurethane can be painted with any interior compositions;

- does not change color under the influence of sunlight;

- Anti-static smooth surface does not attract dust and is easy to clean.

Flaws:

- the material is combustible and fire hazardous;

- the choice of ceiling design is limited to typical elements.

Polyurethane stucco molding looks practically no different from gypsum. With a smooth surface, it completely imitates the decor of fine-grained gypsum. Due to its low weight, it can be mounted not only on plaster, but also on.

Note! Chinese-made polyurethane elements are cheaper, but their quality is lower. Therefore, it is better not to save money and pay attention to trusted manufacturers.

Stucco molding from expanded polystyrene

The most budgetary and affordable option for stucco molding. Expanded polystyrene is a familiar foam with a finer foam structure. Everyone is familiar ceiling tiles and plinths from this material. Polystyrene decor has a minimum weight, so it can be used on any ceiling finish, even on tension structures.

Advantages of polystyrene:

- low price;

- simple installation;

- moisture resistance.

Flaws:

- low mechanical strength, with careless installation or washing, scratches and dents form on the surface;

- a rather loose surface quickly accumulates dust and becomes untidy;

- polystyrene burns and melts with the release of toxic gases;

- the choice of elements is small.

Polystyrene stucco is usually used for budget repairs. At the same time, well-chosen decorative elements can transform the ceiling and give it elegance and style, while finishing costs will be low. To give the polystyrene stucco a more natural look, it can be coated with a water-based paint.

Note! It is impossible to use nitro enamels for painting such stucco! Under their influence, polystyrene is destroyed.

Stucco decoration elements

Stucco is the general name for relief details used in ceiling decoration. They can be decorated with geometric patterns or floral ornaments, convex patterns on any subject. As a rule, traditional elements are used in classic style decoration.

Separately, you need to talk about the cornices of hidden lighting. They are usually made from prefabricated polyurethane elements and attached to the plane of the wall, leaving a gap of 50-60 mm to the ceiling. Inside the eaves there is a niche for fastening led strip. With this element, built-in lighting and the effect of a soaring ceiling are created.

Creating a single image from individual elements is not an easy task, even experienced designers do not always cope with it. Therefore, before proceeding with the manufacture of stucco molding and mounting it on the ceiling, it is worth drawing a sketch or choosing a suitable option for the finished finish. A few photographs with examples of stucco are shown below.

![]()

Manufacturing technology and plaster moldings

Making gypsum stucco with your own hands is a rather painstaking process, it includes:

- preparing or making molds;

- casting blanks;

- fixing stucco on the ceiling;

- ceiling finish.

The most difficult and crucial stage is the manufacture of the mold. You can use the finished form of polyurethane or metal coated with a layer of Teflon, but it’s not always possible to find exactly what you have in mind on sale. You can make the form yourself, but this process takes time.

Preparing a mold for plaster moldings

For the manufacture of each form, you will need a sample for copying - a stucco element of the desired shape. It can be molded with your own hands from plasticine or polymer clay. You can also buy ready-made polyurethane or polystyrene samples, mold them into a mold and cast the required number of plaster elements.

This method is appropriate if you plan to decorate the ceiling with a large number of complex stucco elements.

Required materials and tools:

- silicone and silicone oil for precise casting;

- gauze or fine mesh for its reinforcement;

- building gypsum, cement and PVA glue to stiffen the casting;

- wax release agent in the form of an aerosol for processing the base part;

- narrow brush made of natural hair;

- spatula according to the width of the proposed casting and narrow, 3 cm;

- gun for silicone balloon;

- dense polyethylene.

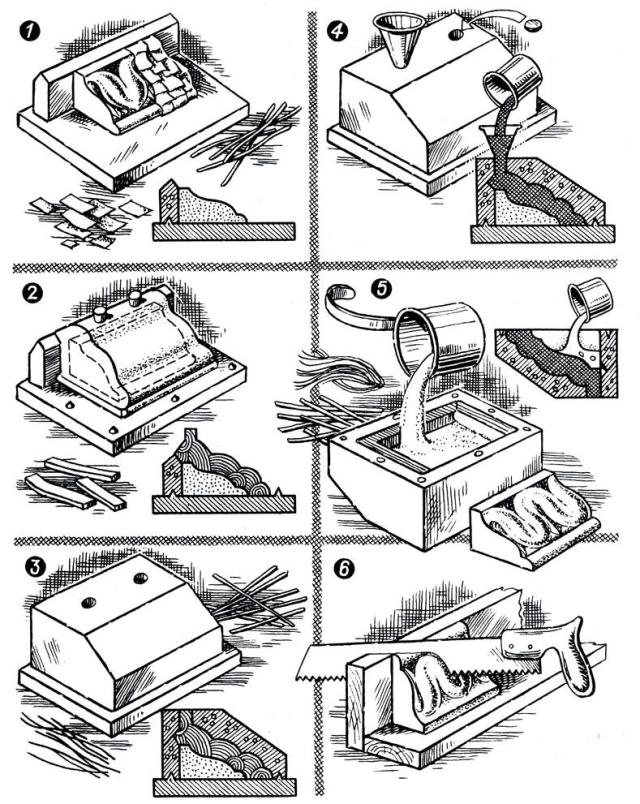

Instructions for making molds based on finished elements are described in Table 1.

Table 1. Technology for making molds for gypsum stucco.

| Steps, illustrations | Description of actions |

|---|---|

| The copied element must be laid on a flat surface covered with dense polyethylene. If the element is long, such as a cornice or molding, and does not fit on the table, drywall trimmings can be used as a base. In order for the form to turn out to be even when pouring, the surface must be strictly horizontal, you can check this using a level. The element to be copied is placed on the surface prepared and treated with a release agent, with the embossed side up. The surface of the element is treated with a release agent. |

| Prepare the silicone solution. To do this, silicone oil is added to acrylic silicone to increase plasticity and the resulting solution is thoroughly mixed. Plasticity is important for stucco elements with a large number of small relief details; pure silicone can be used for simple smooth surfaces. |

| The silicone solution is applied to the base with a thin brush, carefully smearing small details and filling all the recesses. The brush also helps to remove air bubbles, which, after drying, form shells and impair the quality of the finished casting. Silicone is applied to all surfaces, including side and end. The first layer of silicone should be 0.5-1.0 cm. If possible, you need to monitor the uniformity of the application of silicone. |

| To give the silicone mold strength, it is reinforced with gauze or soft mesh in two or three layers. Cut out the fabric with a margin so that it covers the entire base, including the sides. Lubricate with silicone with a brush, making sure that there are no voids. Each subsequent layer is laid with gauze and coated with a silicone solution. It is not necessary to dry the layers. |

| After setting the reinforced silicone layer, it is necessary to strengthen weak points - the sides, especially convex places. This is done using pure silicone, which is applied from a cylinder with a gun. Level the silicone with a finger dipped in water or with a wet rubber spatula. Silicone should completely cover all sides and relief part of the form. |

| The silicone mold is surrounded by formwork, into which the plaster "bed" will be poured later. Formwork can be made from any materials at hand: wood, plastic, dense rubber. The main thing is to give the formwork sufficient rigidity, and cover the rough surface with any smooth material, for example, polyethylene. The joints between the formwork and the silicone mold are smeared with silicone residues to avoid leakage of the gypsum mortar. |

| Gypsum mortar is being prepared. To increase the strength, ¼ of the volume of cement is added to dry building gypsum. The dry composition is diluted with water in which PVA glue is diluted - it will give the solution plasticity and increase the strength of the finished form. The solution is thoroughly stirred and, until it begins to set, fill the formwork with it. All irregularities are smeared with a brush. With a spatula, gently pierce the thickness of the solution to remove air bubbles, but do not damage the silicone layer, and then level it. |

| The last layer of gypsum mortar is carefully leveled with a spatula - it must be strictly horizontal. After the initial setting of the solution, the horizontalness is checked by level. Sometimes excess water appears on the surface of the solution. In order for the solution to set faster and more evenly, they must be removed. To do this, a hole is made at the edge of the formwork, the water is carefully driven off with a spatula and poured into any container. |

| Dry the filled mold for 12-24 hours, depending on the size. This should be done at room temperature and normal humidity. It is impossible to speed up the drying process by heating - the gypsum may crack. After drying, the formwork is carefully removed and excess gypsum mortar is removed. |

| Carefully remove the silicone mold from the plaster "bed". Cut off excess silicone with a sharp knife. Dry separately in air for another day until complete removal of moisture and strength. After that, you can put the silicone mold back into the "bed" and start casting the stucco details. |

Note! It makes sense to make a plaster "bed" only if the form is needed for a large number of castings, and the element itself is quite massive. Reinforced silicone is suitable for the manufacture of small elements.

Production and installation of plaster moldings

The process of making plaster moldings is quite simple.

For the manufacture of stucco elements you will need:

- building plaster;

- PVA glue;

- silicone or wax based release agent.

Table 2. Step-by-step instruction for manufacturing and installation.

| Steps, illustrations | Description of actions |

|---|---|

| Prepared and thoroughly dried forms are cleaned of dust and dirt. Apply a layer of release agent to the inner surface with a brush or sprayer. Make sure that all areas are carefully processed, but the grease does not accumulate in the recesses. It will be impossible to get a casting from a poorly lubricated mold without damage. Forms after lubrication are side by side so as to immediately pour a single portion of the solution into them. They must stand strictly horizontally, otherwise the base will turn out to be uneven. |

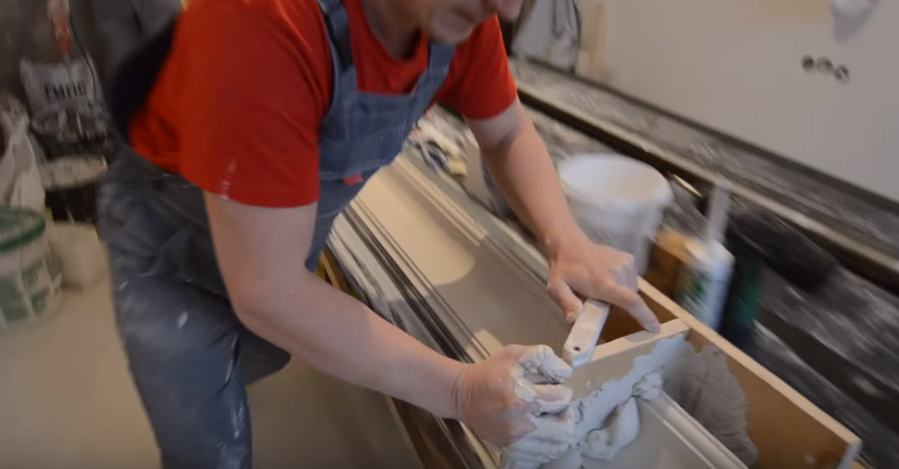

| Knead the gypsum mortar. For stucco molding, it is better to take gypsum grades G4-G7, it sets quickly and has high strength in finished products. Dry powder is poured into a strong container of sufficient size. Prepare a construction mixer. If it is not there, a screwdriver with a nozzle from a household mixer will do. Water at room temperature is mixed with PVA glue, after which it is poured into dry gypsum in small portions and mixed. The consistency of the finished solution should not be thicker than kefir. The solution is quickly poured into prepared molds, punched with a soft brush and leveled with a spatula. |

| The solution sets quickly, but it takes several hours to completely solidify. Gypsum turns white as it dries. The casting is removed from the mold by gently tapping on its bottom. If the mold is well smeared, there is usually no problem. The finished product is placed on a flat, dry surface for final drying and curing, usually 24 hours is enough for this. |

| If there are flaws on the surface of the workpiece, they are cleaned with a fine-grained sandpaper - zero. Sinks can be carefully smeared with gypsum mortar. On the back of the blanks, you need to make risks - they will improve adhesion to the base when installing stucco. Gypsum dust is swept from the workpiece and primed. At the same time, a clean primer for painting is applied to the back surface, and a mixture of primer and paint in a ratio of 1: 1 is applied to the outer surface. After drying, you can paint the outer side of the stucco with interior paint in one or more layers. |

|

Too massive elements are additionally fixed with a few self-tapping screws. To do this, a hole is carefully drilled in the stucco molding, after which the ceiling is marked along them, holes are made there and dowels are inserted. The self-tapping screws are screwed in, sinking the hat in the stucco molding, after which the holes are sealed with gypsum mortar or putty and the stucco molding is painted.

Installation technology of polyurethane and polystyrene moldings

In spite of different properties of these materials, stucco molding is made from them using a similar technology. Polyurethane is trimmed with a hacksaw, polystyrene is cut with a mounting knife. Glue can be used different: liquid nails, PVA or solvent-based polymer glue.

The surface of the ceiling for polyurethane stucco is prepared in the same way as for plaster. Painting and finishing is carried out after its installation. Polystyrene stucco molding can be mounted as a final element after painting the walls and finishing the ceiling.

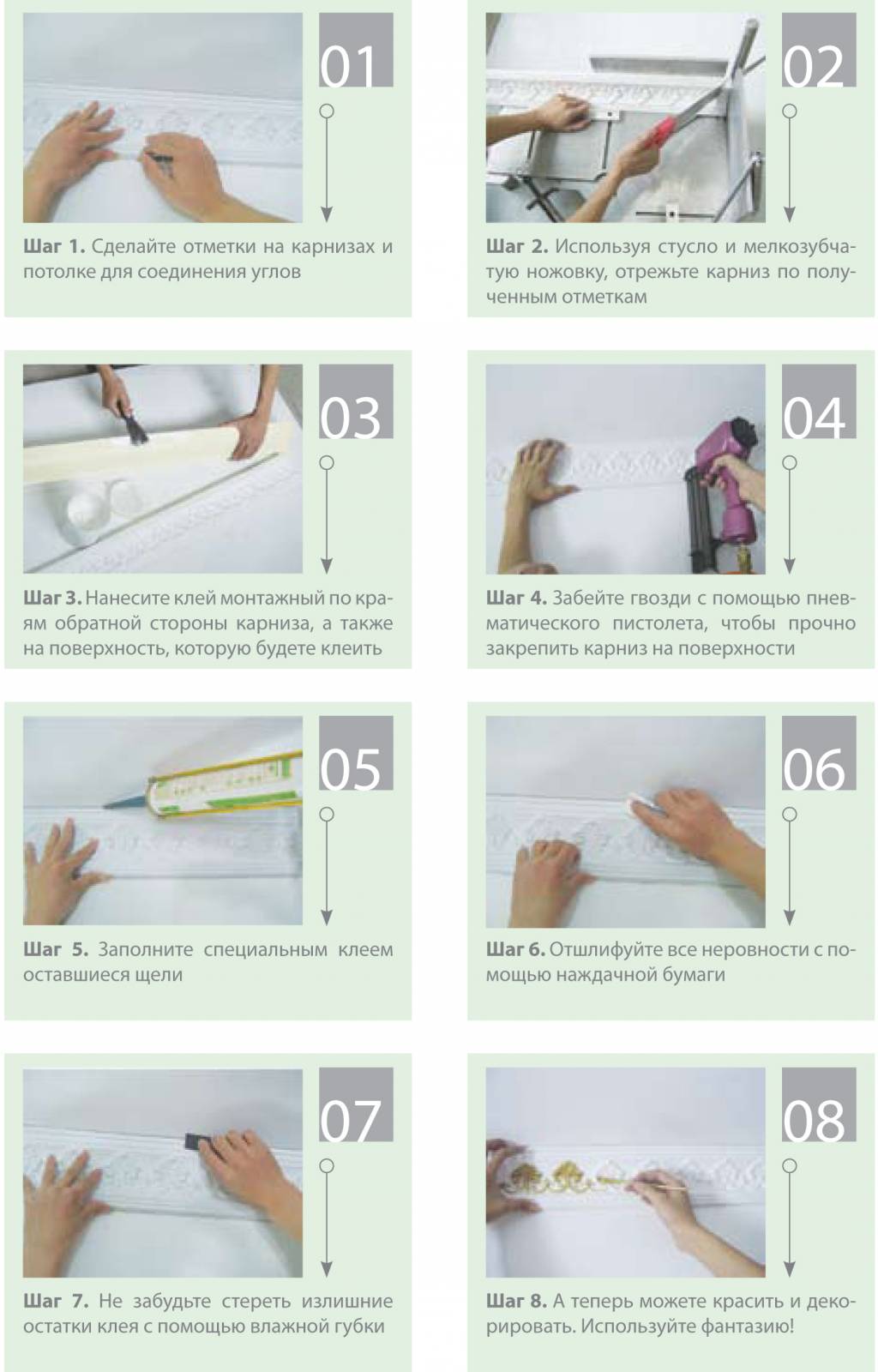

The most difficult stage in the installation of polyurethane stucco molding is the fastening of the cornices. When installing them, it is necessary to join the corners, it is this operation that usually causes difficulties. The video instruction will help to do it correctly and accurately.

Video - Installation of a ceiling cornice

The remaining elements are mounted on a pre-marked ceiling using a similar technology. The back side of the stucco elements is smeared with glue and firmly pressed against the surface of the ceiling. Heavy elements are additionally fixed with self-tapping screws.

After the glue has set, a layer of primer is applied and the stucco molding is painted in the desired color or patina is applied. For a greater resemblance to gypsum stucco, the elements can be pre-puttied, as shown in the video.

Video - Gypsum ceiling socket

Stucco ceilings look stylish and rich at the same time, they exude reliability and comfort. With the help of modern technologies, you can achieve an amazing effect, create a cozy atmosphere and unique design in the house.

This type of ceiling decoration proves once again that classic interior design techniques are always in demand. If the masters have managed to combine the latest technologies with traditional motifs, then you should think about decorative stucco molding on the ceiling. Even a modern suspended or stretch ceiling is easily decorated with stucco decor. Moreover, the choice is wide both in terms of design and in terms of materials used.

Ceiling design with stucco - choose the material

Among the materials used, three main ones can be distinguished. The cheapest and most affordable is expanded polystyrene decor. The designs are very light, in any hardware store you will find a variety of types. To fix it, it is enough to purchase a special glue and simply fix the selected design on a flat surface. Such decorative stucco molding on the ceiling is usually used in budget repair options. However, this price fully reflects the quality: a fuzzy pattern, a very fragile and brittle design. And after installation, cheapness is immediately visible.

Classic stucco ceilings do not accept fakes, and therefore only real gypsum is used for them. After manufacturing, the structure is very durable, it can be sanded and given a finished look. Here the maximum detailing of the picture, a lot of small and clearly visible details. Gypsum is a relatively cheap material, but the work will cost a pretty penny. Only professionals in their field can really work with gypsum with high quality. As for durability, here it is worth considering the ability of the finished decor to acquire a yellowish tint over time. Gypsum also absorbs moisture very well. As an alternative, you should think about gypsum stucco molding on the ceiling from a special moisture-resistant material. And if you use a certain paint, then the decor can even be cleaned with a damp cloth. Polyurethane ceiling stucco molding is one of those options when you can find a compromise. The material is completely not afraid of moisture, the design is no less detailed and after installation it looks no worse than plaster. Big advantage polyurethane ceiling stucco is its ability to maintain its original appearance for a long time, cracks do not form on the surface. As a rule, it is polyurethane stucco molding that is used on a stretch ceiling, since the structures are flexible and curly complex bends are not a problem for them.

Ceiling decoration with stucco - what can I choose?

From the entire list of proposals for decorating the ceiling today, you can pick up the following elements.

Stucco molding on the ceiling has not gone out of fashion at the present time, but is only developing: new materials appear, interesting methods of combining with technologies.

It is difficult to surprise a modern person with anything. The same goes for the interior, in order to stand out, people pay attention to every little detail when decorating a room: walls, windows, floor and ceiling. Therefore, decorative stucco molding on the ceiling in the 21st century is popular, along with multi-tiered hanging and tension structures. It is a three-dimensional relief decoration in the form of molding figurines on the theme of flora, fauna, ancient heroes, mythical creatures or abstract patterns.

Living room interior

This way to decorate a room was known in ancient times, when the palaces of kings and pharaohs amazed with bas-reliefs, columns, stucco patterns on walls and ceilings. Even now living rooms, bedrooms, corridors, large halls and hotel lobbies are finished in this way, especially since the modern materials used for this make it very lightweight and easy to work with. For decoration in a classic style, a stucco ceiling made of plasterboard is best suited.

Stucco design options

Most often, stucco patterns decorate the joints of walls with the ceiling, for this they use polyurethane or foam moldings and cornices, usually they have a traditional White color. The place where the chandelier is attached is decorated with a rosette - stucco molding in the central part of the top, having the shape of a circle, ellipse, square, flower, star, etc. Rosettes can be convex, can be buried in the ceiling, in the form of a niche, they are combined with decorative elements, such as a cornice or individual figurines. Cornices are located inside the outlet or outside. The corners of the ceiling or two opposite sides are also distinguished by separate elements. The design of the putty ceiling with stucco molding makes it possible to hide the cornices for curtains and the place of installation of lighting fixtures.

Stucco in the room looks good if it does not clutter up the space, but causes a feeling of lightness and weightlessness. Such a ceiling would be especially appropriate in the bedroom, where every morning, upon waking up, we are the first to see the ceiling in front of us. Often, stucco is combined with other finishing methods: fabric drapery, wallpaper, wooden details. Even if you have a stretch ceiling in your bedroom, modern materials allow you to install molding on it.

Ceiling design with painted stucco

To highlight the stucco on the ceiling base, it is painted according to the principle of contrast: the main surface is painted, and the stucco remains white. They do the opposite: the ceiling is white or pastel, and the stucco elements can be of a variety of colors. You can make these very elements yourself; ready-made decorative cornices, moldings, balusters, caissons, garlands, and other parts made of foam, polyurethane and gypsum are sold in hardware stores. The main thing is that in the interior of a bedroom or any other room, the ceiling is in harmony with the walls, furniture and other accessories.

Materials for molding on the ceiling

There are many materials for creating stucco masterpieces on the ceiling and walls, and some of them have already become classics, such as:

- gypsum;

- alabaster;

- soft stone.

Others owe their appearance to modern technologies, these are:

- Styrofoam;

- polyurethane;

- fiberglass;

- glass composite.

Let's take a closer look at the features of each of them, starting with the most commonly used ones.

Gypsum

When we hear the word "stucco", the first thing that comes to mind is gypsum. Indeed, this material is now most often used to create complex decorative structures. Plaster molding on white ceiling has advantages over modern materials. This natural mixture, when dried, does not emit a toxic odor, does not support fire, does not shrink over time, is durable and resistant to damage. The only drawbacks can be considered a somewhat large weight of gypsum parts and its ability to absorb moisture. But, despite even these disadvantages, and the high cost, the gypsum ceiling captivates with its uniqueness, environmental friendliness and durability.

Gypsum stucco on the ceiling in the interior

Styrofoam decor is a cheap replacement for plaster. Shops sell ready-made decorative products made of expanded polystyrene, so it is very easy to build a stucco plasterboard ceiling with it: just glue the parts. Due to the fact that the material is very light, such stucco is installed on stretch ceiling and she looks beautiful. But, in addition to the inexpensive price and speed of installation, the foam has its drawbacks: it is very fragile and unstable to damage, it quickly catches fire, so it is not installed near open lamps and fixtures.

Polyurethane

This material is a cross between gypsum and foam, and combines the best properties of both. It is dense and durable, like plaster, but at the same time light and moisture resistant, like foam. Polyurethane does not crack, products made from it are flexible and plastic. It does not melt and is resistant to both high and low temperatures.

Ceiling decoration with polyurethane moldings

Polyurethane structures are also sold ready-made, which is why they are so often used when self repair. Architects and designers consider polyurethane decor in the interior to be the most suitable replacement for classic gypsum.

Fiberglass

Fiberglass is a modern material designed for use in an aggressive environment, withstands large temperature changes, therefore it is used more for outdoor use.

But also ceiling cornices, sockets, moldings, arches, wall panels and other details are made from it. It is very strong and durable, but due to its high cost it is less popular.

Glass composite

Another innovative material will be glass composite or fiberglass. It features light weight, high strength, corrosion resistance, durability and environmental friendliness.

Fiberglass is dyed during production by adding pigments, but can also be dyed after finishing.

Used for indoor and outdoor decoration. Due to its cost, glass composite is used less frequently than polystyrene and polyurethane, but the durability and beauty of such stucco is undeniable.

Tools and materials

If you decide to make decorative elements yourself, then you will need gypsum or alabaster, plain water. From these components, a solution is made from which the figures are poured. To work with plaster or prefabricated structures you will need the following tools:

- dishes for diluting the solution;

- utensils for glue;

- brush for glue;

- narrow spatula;

- teflon figured molds made of alloy steel to create parts;

- PVC molds (sets for children's creativity may well be suitable);

- sandpaper for sanding.

Stucco mounting tools

Materials for fixing decorations under the ceiling are as follows:

- wallpaper glue, polymer or PVA;

- dowel;

- liquid Nails.

If glue is used, then it must be applied to the part carefully to the very edges, so that the line of the indicative drawing on the plasterboard ceiling is hidden after gluing. But you also need to make sure that the glue does not protrude beyond the part, and immediately wipe it with a dry cloth. If the glue seemed liquid, after applying it to the stucco, you should wait until it thickens a little, and then you can glue it.

In the case of mounting on dowels, the stucco molding on the ceiling will be held more securely, and the places where the screws are screwed in are carefully covered with the same plaster.

But the most preferred fasteners are liquid nails. They glue the structure very firmly, and this strength is maintained for a long time in both dry and wet rooms. They do not harm the ceiling covering, so that after dismantling the stucco molding, the ceiling will not suffer.

Care and restoration of stucco

Ceilings with polyurethane stucco are easier to arrange at home, it is available in finished form, while gypsum parts are often made independently. Polyurethane decor is in no way inferior to gypsum or alabaster in terms of quality or appearance, but whatever the material of manufacture, over time, such beauty requires restoration.

To restore elements of gypsum stucco molding, creative skills and materials will be required.

As for care, this is done in a “dry” way: dust is collected with a rag or vacuum cleaner. If it is laminated polyurethane, then it can be washed with a damp sponge.

Stucco repair is done as follows: they clean the damaged surface, if it is made of gypsum, then restore it using the same form, completely crumbling products are replaced with new ones. If there are too many cracked layers of water-based paint, it is cleaned with a dry cloth and a new one is applied. If the paints are oily, then they are removed with a special solution. Next, paint with a narrow brush.

Classic stucco ceilings in the interior of an apartment and a private house look rich and unusual. You can decorate the plasterboard ceiling in this way on your own, resorting to advice from online articles and having some skills in the repair business.

The artistic ceiling has always been and remains now a manifestation of a particularly refined taste and desire to show their financial solvency. At the same time, decorative elements play an important role in its design. First of all, it is stucco on the ceiling. She is not only able to decorate the base, but also mask its defects.

A little about the stucco ceiling

Now in the construction market there is no shortage of decorative elements for the stucco ceiling. You can purchase a variety of components, using which you can assemble a variety of decorative compositions.

At the same time, natural gypsum, from which stucco is traditionally poured, is gradually losing ground. He competes more and more artificial materials and stamped decor, visually almost indistinguishable from analogues made by hand.

Thanks to this, anyone who wants to improve the aesthetics of the interior of their home can now decorate artistic ceilings.

But those of you who want to arrange an artistic ceiling on your own will face certain problems. This article will help you resolve them. First of all, you need to choose which stucco molding for the ceiling will be used. Now the most in demand are three materials for the manufacture of such decor.

What materials are used, their pros and cons

In the construction market, you can find handmade decor cast from plaster, as well as stamped elements from foam and polyurethane. Let's analyze their features, advantages and disadvantages.

Material No. 1: foam, aka expanded polystyrene

Expanded polystyrene is often popularly referred to as polystyrene foam. The first company that began to supply it to the Soviet Union was from Finland,

The advantages of the material are:

- Styrofoam decor is the cheapest. This circumstance makes it possible to save on repairs.

- The elements made of this material are very light.

- Expanded polystyrene is flexible, this allows you to design ceilings of the most complex configuration. In addition, this quality makes it possible to decorate with foam not quite even surfaces.

- Installation of such decorative elements is extremely simple and easy. The foam is easy to cut.

- To install parts, they only need to be glued with a special compound.

In addition to the advantages, polystyrene foam has significant disadvantages:

- The pattern and patterns on the decorative elements of it are fuzzy. As a result, it is not possible to focus on small details of the decor. It is not possible to rectify such a state of affairs.

- The second most important disadvantage of polystyrene is that it is fragile and brittle. He is afraid of mechanical and shock effects. Therefore, when installing with decor, you must handle it very carefully. If you break it, and you do not have a supply of parts, it will be impossible to make up for the loss.

- The material is combustible.

- Another important disadvantage, already from an aesthetic point of view. Stucco molding on the ceiling made of polystyrene foam looks too cheap, and you can’t hide it with anything. As a result, many amateur builders choose decor from more expensive materials.

Material No. 2: decorative plaster elements

Gypsum and alabaster stucco is a traditional ceiling decor option. The ancient Egyptians, then the Greeks, and then the Romans decorated their palaces with it.

These peoples made it fashionable to decorate their homes with plaster and alabaster figures of legendary heroes and gods.

It was during the ancient period that the first forms were invented, which made it possible to cast decorative finished parts. During the Renaissance, the forgotten tradition of decorating the ceiling with stucco was restored and used in classical design styles: antique, baroque, rococo, empire.

The best examples of artistic ceilings using plaster moldings adorn the apartments of the palaces of royals and royalty. For example, the Winter Palace in St. Petersburg or Versailles in Paris.

Since then, practically nothing has changed, because the technology, as time has shown, turned out to be simple and perfect. So, now the aesthetics of the artistic ceiling is actively used by neoclassical design.

Gypsum, as a material for stucco molding, outperforms polystyrene in many respects:

- After hardening, it turns into a solid and dense composition.

- At the same time, the material is easy to process: cut, grind, drill.

- With the help of a cutter, you can work out every recess, every curl of the pattern in all, even the smallest details. The pattern is then brought to perfect beauty with fine-grained sandpaper.

The result of the work is the original decor, which is not shameful to decorate any chic home.

- Gypsum and alabaster stucco create a voluminous and clear relief. It can be composed into very complex and original compositions.

- This decor can be molded into any shape.

- The material is not combustible.

- The resulting artistic ceiling looks great and can satisfy any, even the most sophisticated requirements.

- Another very important advantage of the material is that gypsum is able to withstand medium mechanical stress. It is very difficult to damage or pierce products from it, like foam analogs.

In the photo - the restoration of plaster moldings.

- Even if something happens to such decor, it can always be restored.

About the disadvantages of gypsum:

- Mounting gypsum stucco is quite difficult. This requires certain skills, as well as labor and time costs. However, the result of the work justifies all the "torment".

- Gypsum decor may turn yellow over time.

- The material is brittle and does not withstand impact.

- Among other things, it is hygroscopic, so it absorbs and releases water well. This feature, as well as temperature differences, contributes to the beginning of the process of destruction of the material.

The decor begins to crumble, small cracks appear on it, which destroy it during subsequent expansion. The item is not recoverable.

You can extend the long service life of the gypsum decoration without this. For this decoration should be covered with a layer of paint. Acrylic water-dispersion composition is best suited for this purpose. The painted ceiling with stucco can even be washed.

Material No. 3: polyurethane decor

Having barely appeared on the construction market, decorative elements made of polyurethane immediately seriously pressed their competitors from other materials. Ceiling decorations made from this polymer combine the best properties of synthetic polystyrene foam and natural gypsum.

Advantages of polyurethane:

- The material has good moisture resistance.

- It is heavier than foam, but much lighter than plaster.

- Polyurethane is the most durable of the three materials presented. It withstands all mechanical stress well and does not crack over time.

- Decorative elements made of this polymer plausibly imitate the texture of natural gypsum and are able to clearly convey the smallest details of patterns.

- The material is easy to process.

- Due to their resistance to melting, polyurethane decorations can be mounted close to lighting fixtures.

- The material is flexible and plastic, thanks to which it can be given the desired radial and complex shape.

- A separate advantage that polyurethane stucco ceilings have is the speed of installation work and the ease of their subsequent processing.

On the construction market, you can purchase two types of polyurethane ceiling moldings: laminated and primed elements.

- The first of them are used only for decoration of the internal areas of the house.

- The second variety can withstand difficult street conditions. The price of such decor is quite high.

What to choose: polyurethane or plaster

Almost all of us who want to decorate artistic ceilings in our home face a similar problem of choice. Here you can advise to approach the solution of the problem in a strictly individual manner.

It's one thing when an author's, unique design of an artistic ceiling is created. In this case, the best choice is interior design in one of the classic styles or the creation of their original replica according to the “neoclassical” direction. Here it is best to prefer manual work, that is, plaster molding.

When repairs are done on their own, without using the services of professional decorators, or you need to carry out work in a short time, best choice- decorations made of polyurethane.

Due to the plausibility of imitation by polyurethane natural material, ceilings will look just as aesthetically pleasing and respectable as with plaster decor.

Ceiling decor elements

Ceilings can be decorated with such decorative basic elements.

- Caissons are square or polygonal recesses. In past centuries, they were decorated with vaulted ceilings.

At the moment, the scope of use of this decorative element has grown significantly. With the help of caissons, flat ceilings are also decorated, giving them a special relief and depth.

- Ceiling outlets. Such details are usually used to decorate the surface around the chandelier and other lighting fixtures. In most cases, there is a hole in the center of the outlet for the electrical wire.

These elements may have different shapes, embossed patterns or patterns. In addition to decorative functions, sockets also mask technological holes for lighting fixtures and ceiling defects around them.

- Most often, the design of the ceiling with stucco occurs with the help of moldings and cornices (ceiling skirting boards):

- using cornices, you can give the cladding a complete appearance, as well as visually make the ceilings higher. Similar details usually adorn the junctions of the ceiling and walls;

- moldings perform the same function. However, they are usually used when you need to mount a hidden type.

- Decorative elements in the form of domes. A similar concave design is used on non-standard ceilings.

A room decorated with such decorations takes on the appearance of a Baroque apartment. If you mount a crystal chandelier inside the decorative dome, the room starts to look just great.

Features of the installation of stucco

Mounting decorative elements on the ceiling is not too difficult. The main thing is to correctly organize the work and select the right materials and tools.

At the same time, the installation features of gypsum decorative elements differ from the installation of polymer parts.

How to attach jewelry

To fix the ceiling decor you need:

- If stucco molding from polystyrene or gypsum is chosen, then construction adhesive based on polyvinyl acetate (PVA).

If decorative gypsum elements are massive and large, then PVA glue mixed with alabaster is often used for their fastening. Sometimes such a heavy decor is also fixed with dowels with self-tapping screws.

- If you chose polyurethane jewelry, then you will need “liquid nails” to attach them. This construction adhesive has a holding power 10 times greater than PVA. It is not capable of spoiling the decor coating.

Before purchasing, carefully read the annotation on the packaging of the adhesive. There are different types of liquid nails on the market. So, they can be designed for repairs in wet or dry rooms. Some compositions may contain hazardous substances, so they cannot be used in living rooms.

When installing decorative polyurethane elements in the living room, bedroom, children's room, only water-dispersion glue "liquid nails" is suitable. In this case, select the composition that has the shortest setting period.

Installation of decorative plaster elements

You can purchase ready-made gypsum ceiling decor on the construction market.

Or, if you have the skills and the appropriate tools, cast it yourself:

- The gypsum decor is attached with PVA glue, it is densely distributed along the back side of the element.

- All squeezed out excess of the composition should be removed immediately with a damp sponge.

- The joints between the stucco and the wall and the seams between the details are leveled with any putty, which includes PVA.

- When the decor dries, all joints are sanded and sanded.

Gypsum decorative elements should be mounted before the finishing painting of the ceilings. It is best to paint them together with the already installed stucco molding.

Installation of polyurethane and foam moldings

The installation of elements made of polyurethane has its own characteristics.

It is highly desirable that the decorative details lie in a heated room for several days before their installation. So their temperature will be equal to room temperature.

The manufacturer's instructions usually indicate which adhesive should be used to fix the parts to the ceiling and to each other.

Polyurethane and polystyrene stucco should be painted only after the adhesive has completely cured. At the same time, only water-dispersion coatings are suitable for polystyrene, and any paints are suitable for polyurethane.

Conclusion

The choice of stucco decoration for the ceiling is an important process. The level of aesthetics of the interior, as well as the technology for installing decorations, depends on its results. Take the choice seriously and as a result get a unique design of your home. The video in this article continues with "width="640" height="360" frameborder="0" allowfullscreen="allowfullscreen">

Conclusion

The choice of stucco decoration for the ceiling is an important process. The level of aesthetics of the interior, as well as the technology for installing decorations, depends on its results. Take the choice seriously and as a result get a unique design of your home. The video in this article will continue her theme.